Anwansi nke ụwa microscopic, kpọga gị ka ị chọpụta nano-electrolating

N'oge mmepe ngwa ngwa nke sayensị na teknụzụ,nanotechnology dị ka kpakpando ọhụrụ na-egbuke egbuke, na-egbuke egbuke n'akụkụ dị iche iche. Dị ka nkà na ụzụ electroplating na-apụta, nano-electroplating na-ejikọta nanotechnology na usoro electroplating omenala. Site na iwebata nanomaterials ma ọ bụ na-achịkwa nanostructure nke mkpuchi n'oge usoro electroplating, a na-enweta ihe mkpuchi nwere arụmọrụ dị mma. Isi ihe bụ iji ihe pụrụ iche nke nanoparticles, dị ka ebe dị elu dị elu, ọrụ dị elu na ihe pụrụ iche nke anụ ahụ na kemịkal, iji melite arụmọrụ nke oyi akwa electroplating. N'oge usoro electroplating, enwere ike ịgbasa nanoparticles na ngwọta electroplating dị ka ihe mgbakwunye. Ka usoro electroplating na-aga n'ihu, a ga-edobe ihe ndị ahụ nanoparticles n'elu nke mkpụrụ ahụ ma na-emepụta ihe mkpuchi na-ejikọta ya na ion electroplating ndị ọzọ. Ihe mkpuchi a ọ bụghị naanị nwere nchebe na ọrụ ịchọ mma nke mkpuchi electroplating omenala, ma nweekwa uru arụmọrụ pụrụ iche.

Ⅰ Uru arụmọrụ isi nke mkpuchi nano-electrolating

1. Isi ike na iyi mgbochi

N'ihi mgbakwunye nke nanoparticles, ike nke mkpuchi electroplating emeela ka ọ dịkwuo mma. Dịka ọmụmaatụ, mgbe agbakwunyere nano-diamond particles na nickel-phosphorus electroplating omenala, ike nke mkpuchi nwere ike ịbawanye ọtụtụ ugboro ma ọ bụ ọbụna ọtụtụ ugboro. Nke a elu-ike ike mkpuchi nwere sara mbara ngwa atụmanya na n'ibu nhazi, aerospace, ụgbọala n'ichepụta na ubi ndị ọzọ. Ọ nwere ike belata ihe eji arụ ọrụ nke ọma ma gbasaa ndụ akụrụngwa, ebe ọ na-emeziwanye izi ezi na ntụkwasị obi nke akụrụngwa.

2. Nguzogide corrosion

Nguzogide corrosion nke mkpuchi nano-electroplating emeela ka ọ dịkwuo mma. Nanoparticles na-etolite microstructure pụrụ iche na mkpuchi. Ihe owuwu a nwere ike igbochi mwakpo nke mgbasa ozi na-emebi emebi nke ọma, si otú a na-emeziwanye nguzogide corrosion nke mkpuchi. Dịka ọmụmaatụ, mkpuchi nke e guzobere site na ngwakọta electroplating nke nano-ceramic particles na metal ion nwere ọtụtụ ugboro ma ọ bụ ọbụna ọtụtụ ugboro dị elu corrosion eguzogide karịa omenala electroplating mkpuchi. Enwere ike iji mkpuchi a mee ihe n'ọtụtụ ebe na injinia mmiri, akụrụngwa kemịkalụ, ngwaọrụ eletrọnịkị na mpaghara ndị ọzọ iji nye nchebe mgbochi corrosion ogologo oge maka akụrụngwa.

3. Ngwa anya

Nano-electrolating mkpuchi nwekwara ihe pụrụ iche ngwa anya. N'ihi oke mmetụta nke nanoparticles, mgbe ìhè na-agbanye n'elu mkpuchi ahụ, ihe mgbagwoju anya pụrụ iche, absorption na ntụgharị uche na-eme. Dịka ọmụmaatụ, mkpuchi nke e mere site na ngwakọta electroplating nke nano-silver particles na metal ion nwere ike igosi mmetụta anya pụrụ iche, dị ka mgbanwe agba na ụbara gloss. Enwere ike itinye mkpuchi a na ngwaọrụ anya, ihe ịchọ mma na ubi ndị ọzọ, na-agbakwunye mmetụta ọhụụ pụrụ iche na ngwaahịa

4. Ngwa eletriki

Njirimara eletriki nke mkpuchi nano-electrolating ka emezikwara nke ọma. Ụfọdụ nanoparticles nwere conductivity pụrụ iche ma ọ bụ semiconductor Njirimara. Mgbe a na-etinye ha na ion metal, ha nwere ike ịmepụta mkpuchi nwere ihe ọkụ eletrik kpọmkwem. Dịka ọmụmaatụ, mkpuchi nke mejupụtara electroplating mejupụtara nano-carbon tubes na metal ion nwere ezigbo conductivity na electromagnetic shielding Njirimara. Enwere ike itinye mkpuchi a na ngwa eletrọnịkị, ngwa nzikọrịta ozi na mpaghara ndị ọzọ iji melite ndakọrịta elektrọnik na ọrụ nnyefe mgbaàmà nke akụrụngwa.

Ⅱ Ebe isi ngwa nke nano-electroplating

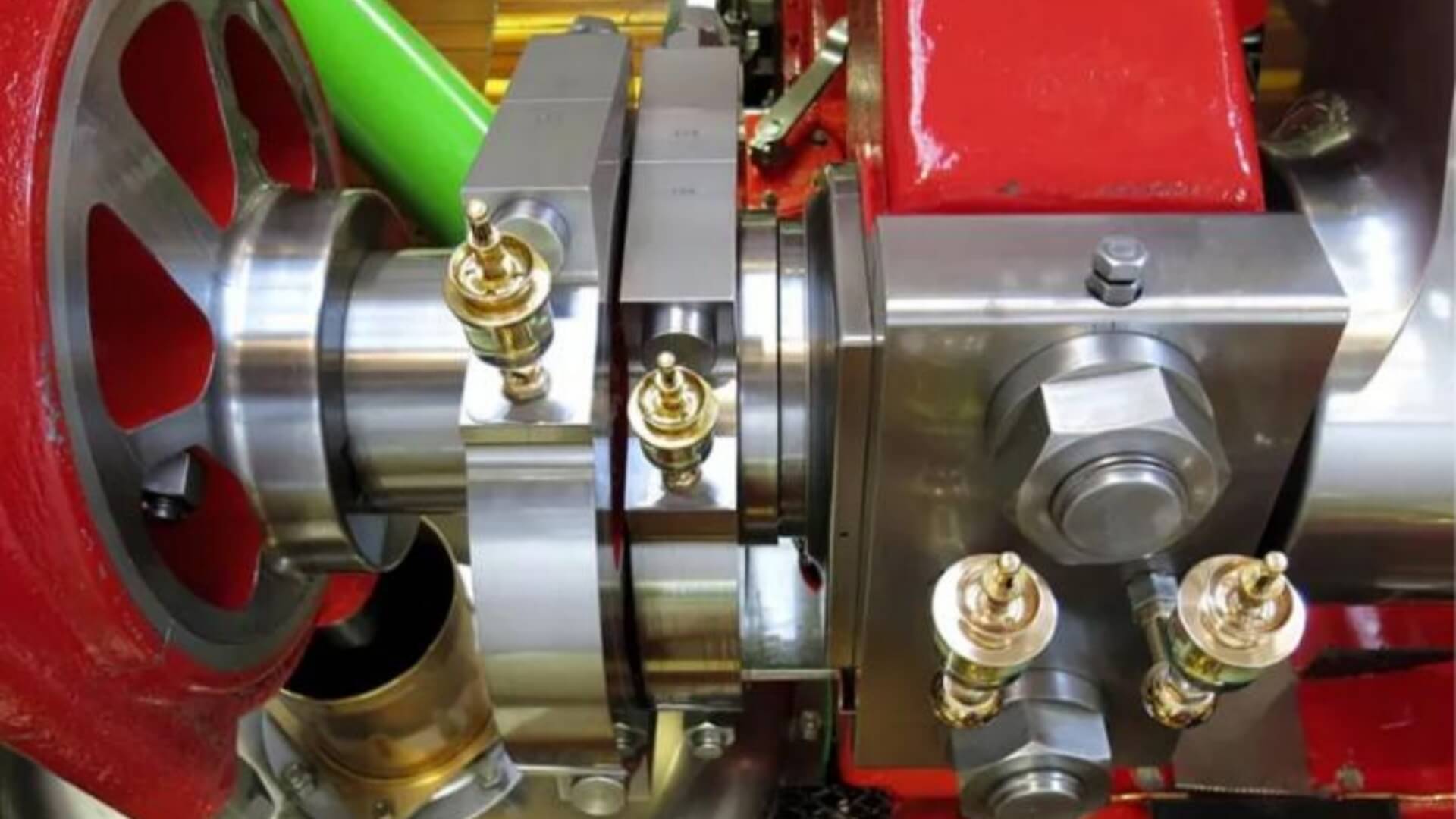

1. Mechanical nrụpụta

N'ihi mgbakwunye nke nanoparticles, ike nke mkpuchi electroplating emeela ka ọ dịkwuo mma. Dịka ọmụmaatụ, mgbe ị gbakwunyere nano-diamond particles na nickel-phosphorus electroplating omenala, ike nke mkpuchi nwere ike ịbawanye ọtụtụ ugboro ma ọ bụ ọbụna ọtụtụ ugboro. Nke a elu-ike ike mkpuchi nwere sara mbara ngwa atụmanya na n'ibu nhazi, aerospace, ụgbọala n'ichepụta na ubi ndị ọzọ. Ọ nwere ike belata ihe eji arụ ọrụ nke ọma ma gbasaa ndụ akụrụngwa, ebe ọ na-emeziwanye izi ezi na ntụkwasị obi nke akụrụngwa

2. Aerospace

Mpaghara ikuku ikuku nwere oke arụmọrụ dị oke mkpa maka ihe, chọrọ ike dị elu, ike siri ike, akwa mkpuchi akwa, nguzogide corrosion dị elu na ihe ndị ọzọ. Nano-electroplating mkpuchi nwere ike izute ndị a chọrọ na-eji na-arụpụta aerospace engine akụkụ, ụgbọelu elu mkpuchi, wdg Dị ka ihe atụ, coatings kpụrụ site composite electroplating nke nano-seramiiki ahụ na metal ion nwere ike n'ụzọ dị irè melite eyi nguzogide na elu okpomọkụ iguzogide nke engine akụkụ, ma na-ebelata arọ nke akụkụ na imeziwanye mmanụ ọkụ arụmọrụ na ụgbọ elu arụmọrụ nke ụgbọ elu.

3. Eletrọnịkị na ngwa eletriki

N'ihe gbasara ngwá electronic na ngwa eletriki, enwere ike iji mkpuchi nano-electroplating rụọ ọrụ dị elu na-arụ ọrụ eletrik na mbadamba sekit. Dịka ọmụmaatụ, mkpuchi nke e mepụtara site na ngwakọta electroplating nke nano-silver particles na metal ion nwere ezigbo conductivity na antioxidant Njirimara na ike ga-eji na-arụ ọrụ elu-arụmọrụ conductive sekit na njikọ. Tụkwasị na nke ahụ, a pụkwara iji mkpuchi nano-electroplating mee ihe iji mepụta ihe mkpuchi electromagnetic iji gbochie nnyonye anya electromagnetic ma melite ntụkwasị obi nke ngwá electronic.

4. Ụlọ ọrụ ụgbọ ala

Ụlọ ọrụ ụgbọ ala bụ otu n'ime akụkụ dị mkpa nke nano-electrolating ngwa. Nano-electroplating mkpuchi nwere ike iji rụpụta ụgbọala engine akụkụ, breeki usoro akụkụ, wdg Dị ka ihe atụ, nano-ahụ elu coatings, coatings kpụrụ site composite electroplating nke diamond ahụ na metal ion nwere ike n'ụzọ dị irè melite eyi nguzogide na corrosion iguzogide nke engine piston yiri mgbaaka, si otú ahụ na-emeziwanye ndụ ọrụ na arụmọrụ nke engine. N'otu oge ahụ, a pụkwara iji mkpuchi nano-electroplating mee ihe maka ịchọ mma na nchebe nke ụgbọ ala, na-eme ka glossiness na corrosion na-eguzogide anụ ahụ na ịgbatị ndụ ọrụ ụgbọ ala.