Ngwaahịa

Platelet Calcined Alumina ntụ ntụ

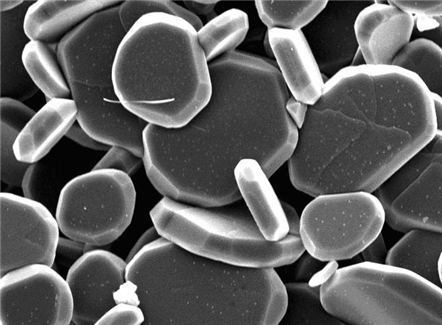

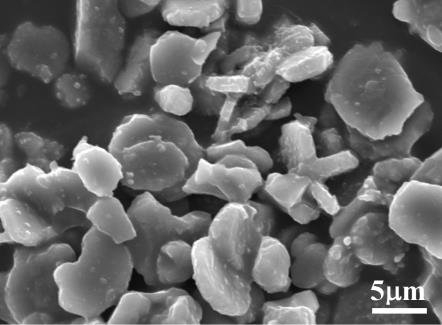

Plate Calcined Alumina polishing powder bụ nke nnukwu ụlọ ọrụ mmepụta ihe alumina ntụ ntụ dị ka akụrụngwa, na-esikwa ya site na usoro mmepụta pụrụ iche. Ọdịdị kristal nke ntụ ntụ alumina emepụtara bụ hexagonal flat dị ka tabul, yabụ a na-akpọ ya Platelet Alumina ma ọ bụ Tabular Alumina.

Platelet Alumina bụ ụdị alumina dị elu nke nwere ntụ ntụ ntụ, nke nwere kristal nke Al2O3 nwere efere nwere ịdị ọcha karịa 99.0%. Ọ nwere ezigbo ihe na-egbochi okpomọkụ yana ịbụ nke na-adịghị ahụkebe, ma acids ma ọ bụ alkalines adịghị emebi emebi. Ebe ọ bụ na a na-achịkwa nkesa nke Platelet Alumina nke ọma, ọ nwere ike mepụta elu dị mma nke ukwuu, na-enye ya ọrụ dị oke mma dị ka ihe na-ekpo ọkụ. N'iji ọtụtụ ihe eji arụ ọrụ, Platelet Alumina bụ ntụ ntụ na-ekpochapụ nke nwere ike ịrụ ọtụtụ ọrụ.

Tabular alumina ntụ ntụ

Tabular alumina ntụ ntụ

Nkọwa ọkọlọtọ maka nha urughuru

| Akara | Nkesa irighiri ihe (µm) | |||

| Oke urughuru | Nha urughuru | Nha urughuru | Nha urughuru | |

| 45 | 82.9 | 53.4± 3.2 | 34.9± 2.3 | 22.8 ± 1.8 |

| 40 | 2.77.8 | 41.8± 2.8 | 29.7± 2.0 | 19.0± 1.0 |

| 35 | 64.0 | 37.6± 2.2 | 25.5± 1.7 | 16.0± 1.0 |

| 30 | 50.8 | 30.2± 2.1 | 20.8± 1.5 | 14.5± 1.1 |

| 25 | 40.3 | 26.3± 1.9 | 17.4± 1.3 | 10.4± 0.8 |

| 20 | 32.0 | 22.5± 1.6 | 14.2± 1.1 | 9.00± 0.80 |

| 15 | 25.4 | 16.0± 1.2 | 10.2± 0.8 | 6.30±0.50 |

| 12 | 20.2 | 12.8± 1.0 | 8.20± 0.60 | 4.90±0.40 |

| 9 | 16.0 | 9.70± 0.80 | 6.40±0.50 | 3.60± 0.30 |

| 5 | 12.7 | 7.20±0.60 | 4.70±0.40 | 2.80± 0.25 |

| 3 | 10.1 | 5.20± 0.40 | 3.10± 0.30 | 1.80± 0.30 |

Ọkọlọtọ Ogo

| Ụdị ngwaahịa | Nnukwu ike ndọda | ||||

| Al2O3 | SiO2 | Fe2O3 | Na2O | ||

| 3µm-45µm | 3,90 | 99.0 | 00.20 | 00.10 | 1.00

|

Uru Alumina Powder

1. Jiri ya tụnyere ndị ọzọ tabular ntụ ntụ, na tabular alumina ntụ ntụ nwere magburu onwe Nchikota Njirimara. Dị ka ebe mgbaze dị elu, isi ike siri ike, ike igwe dị elu, nkwụsi ike dị mma, nguzogide kemịkalụ, nkwụsị oxidation na nguzogide okpomọkụ wdg.

2. Ụdị mpempe akwụkwọ dị larịị na-eme ka esemokwu ahụ dịkwuo ukwuu, na-eme ka ọsọ na-egweri na ịrụ ọrụ nke ọma, nke a nwere ike ibelata ọnụ ọgụgụ nke igwe igwe, ọrụ na oge nkwụsị.

3. Ụdị mpempe akwụkwọ dị larịị na-eme ka ihe na-egweri adịghị mfe ịkpụcha, ọnụ ọgụgụ nke ngwaahịa ndị ruru eru nwere ike ịbawanye 10% -15%. Dịka ọmụmaatụ, ọnụego nke silicon wafer semiconductor tozuru oke nwere ike iru 96% ma ọ bụ karịa.

4. Nwere mmetụta abụọ nke nano na micro powders, ọrụ elu dị oke oke, ọ bụghị nanị na ọ nwere ike jikọta ya na ìgwè ndị ọzọ na-arụ ọrụ nke ọma, ma ọ dịghịkwa mfe agglomerate na ịkwado mgbasa ozi dị irè.

5. Nwere ezigbo adhesion, mmetụta nchebe dị ịrịba ama na ikike igosipụta ìhè.

6. The tabular alumina ntụ ntụ bụ ihe fọrọ nke nta ka ọ bụrụ uzo, enweghị agba, ma nwee ebe dị larịị ma dị mma. Kristal nke ọma nke ọma bụ hexagons mgbe niile.

7. The tabular alumina ntụ ntụ nwere ike ime ka ọ bụrụ ezigbo ntụ ntụ polishing.

1. Ụlọ ọrụ Electronics: egweri na polishing nke semiconductor monocrystalline silicon wafers, quartz quartz kristal, compound semiconductors (crystalline gallium, phosphating nano).

2. Glass ụlọ ọrụ: egweri na nhazi nke kristal, quartz iko, kinescope iko shei ihuenyo, optical iko, mmiri mmiri crystal ngosi (LCD) iko mkpụrụ, na quartz crystal.

3. Ụlọ ọrụ mkpuchi: mkpuchi pụrụ iche na ihe nkpuchi maka ịgbasa plasma.

4. Metal na seramiiki nhazi ụlọ ọrụ: nkenke seramiiki ihe, sintered seramiiki ngwaọrụ, elu-ọkwa elu okpomọkụ mkpuchi, wdg.

Ajuju gi

Ọ bụrụ na ị nwere ajụjụ ọ bụla. Biko nweere onwe gị ịkpọtụrụ anyị.