Ngwaahịa

Sịntetik Diamond Polishing Micro ntụ ntụ

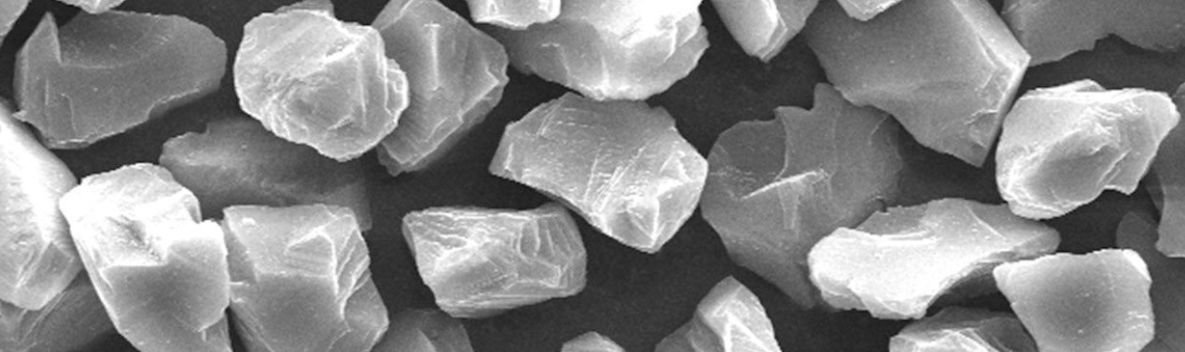

Monocrystalline diamond ntụ ntụ

Monocrystalline Diamond ntụ ntụ na-emepụta site na diamond artificial single crystal abrasive grains site na usoro nrụgide static, nke a na-echipịa ma kpụzie ya site na iji usoro pụrụ iche maka ihe ndị siri ike. Akụkụ ya na-ejigide otu njirimara kristal nke otu diamond kristal.

| Nkọwapụta | D50 (μm) | Nkọwapụta | D50 (μm) |

| 0-0.05 | 0.05 | 5-10 | 6.5 |

| 0-0.08 | 0.08 | 6-12 | 8.5 |

| 0-0.1 | 0.1 | 8-12 | 10 |

| 0-0.25 | 0.2 | 8-16 | 12 |

| 0-0.5 | 0.3 | 10-20 | 15 |

| 0-1 | 0.5 | 15-25 | 18 |

| 0.5-1.5 | 0.8 | 20-30 | 22 |

| 0-2 | 1 | 20-40 | 26 |

| 1-2 | 1.4 | 30-40 | 30 |

| 1-3 | 1.8 | 40-60 | 40 |

| 2-4 | 2.5 | 50-70 | 50 |

| 3-6 | 3.5 | 60-80 | 60 |

| 4-8 | 5 |

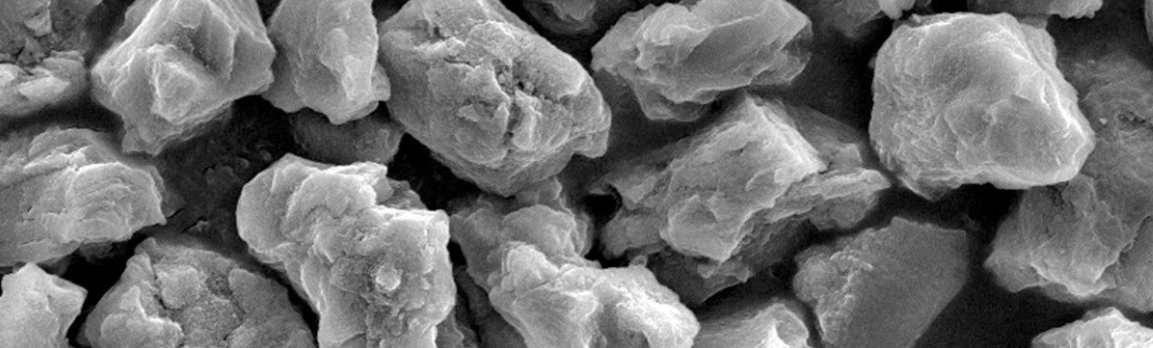

Polycrystalline Diamond ntụ ntụ

Polycrystalline diamond ntụ ntụ bụ micron na sub-micron polycrystalline ụmụ irighiri ihe mejupụtara nke diamond grains na dayameta nke 5 ~ 10nm bonded site unsaturated agbụ. Ime ime bụ isotropic na enweghị ụgbọ elu mgbawa. Nwere nnukwu ike. N'ihi njirimara nhazi ya pụrụ iche, a na-ejikarị ya eme ihe na-egweri na ihicha ihe semiconductor, ceramik ziri ezi, wdg.

Nha dị nke diamond micro powder dị ka n'okpuru:

Njirimara ngwaahịa

-Nfefe kpamkpam wepụrụ

- PSD dị warara

-Ịdị ọcha n'elu nwere ike iru ọkwa ppm

- pụtara dispersibility

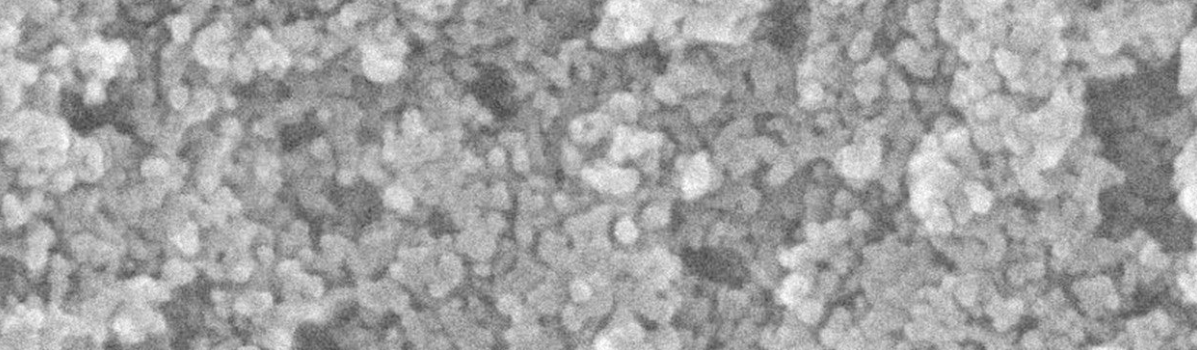

Nano Diamond ntụ ntụ

Emebere ntụ ntụ nano diamond nwere obere kristal dị n'okpuru nanometer 20, ọnọdụ mgbawa pụrụ iche na-emepụta diamond nwere okirikiri nwere otu ọrụ bara ụba n'elu, a na-abawanye mpaghara elu ya kpọmkwem site n'otu usoro ịdị ukwuu dị iche na diamond monocrystalline. Ngwaahịa a abụghị naanị nwere ezigbo ike ike na egweri nke diamond, kamakwa ọ nwere njirimara ọhụrụ nke ihe nanofunctional.

| Nha | ND50 | ND80 | ND100 | ND120 | ND150 | ND200 | ND300 | ND500 | ND800 |

| D50(nm) | 45-55 | 75-85 | 90-110 | 110-130 | 140-160 | 180-220 | 280-320 | 450-550 | 750-850 |

Njirimara

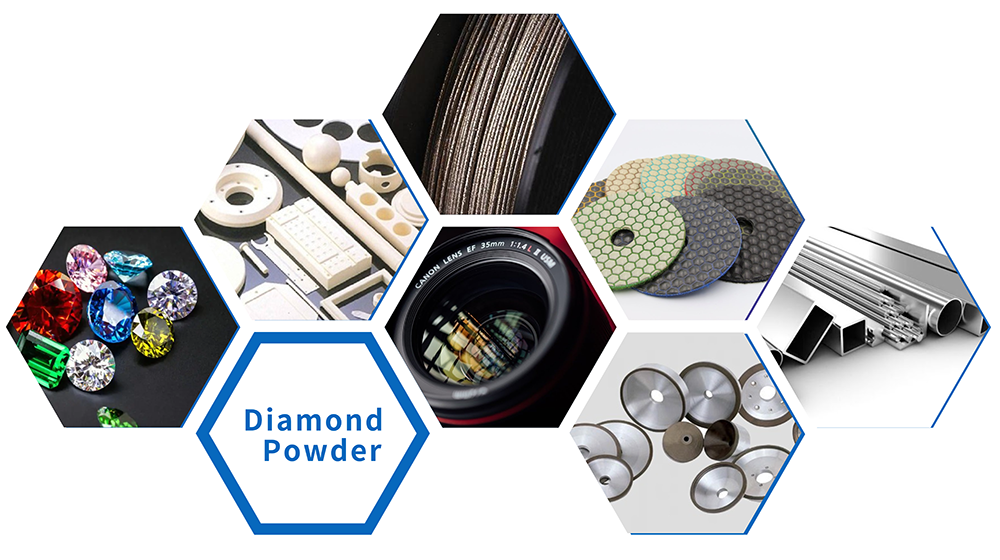

Ngwa Monocrystalline Diamond Powder Ngwa

1. Kwesịrị ekwesị maka eriri diamond dị elu dị elu dị elu, igwe na-egweri diamond electroplated, SiC crystal cutting, knives, ultra-thin saw blades, etc.

2. Kwesịrị ekwesị maka mpempe akwụkwọ diamond composite, diamond polycrystalline na metal bond ngwaahịa, seramiiki bond ngwaahịa, electroplated diamond ngwaahịa, wdg.

3. Kwesịrị ekwesị maka ngwaọrụ diamond electroplated, wiil na-egweri, wdg nke a na-eji maka nhazi ihe siri ike na nke na-adịghị ike.

4. Kwesịrị ekwesị maka ichikota nkenke na polishing nke ihe bara nnukwu uru, lenses, metallographic consumables, LCD panel, LCD glass, sapphire, quartz sheets, LED sapphire substrates, LCD iko, seramiiki ihe, wdg.

Ngwa Polycrystalline Diamond Powder Ngwa

1.Thin na polishing nke semiconductor wafers, dị ka SiC wafer na sapphire.

2.Surface polishing nke dị iche iche seramiiki ihe

3.Surface polishing nke metal ihe, dị ka igwe anaghị agba nchara, aluminum alloy na na

Ngwa Nano Diamond Powder

1. Super mma polishing. Ọdịiche dị n'elu nke workpieces a na-egbu maramara nwere ike iru ọkwa angstrom na-enweghị ọkọ, nke nwere ike imeju ngwa ngwa polishing kacha sie ike.

2. Enwere ike iji diamond Nano dị ka ihe mgbakwunye mmanụ mmanụ. A ga-agbanwe esemokwu na-amị amị ka ọ bụrụ esemokwu na-agbagharị agbagharị, nke nwere ike ibelata ọnụọgụ esemokwu ma melite arụmọrụ esemokwu nke ukwuu ma gbatịkwuo ndụ ọrụ.

3. Composite plating na spraying n'elu nke dị iche iche workpieces, welie eyi eguzogide, corrosion eguzogide, mmetụta siri ike na ike nke workpieces 'elu.

4. Dị ka roba na plastic mgbakwunye, nano diamond nwere ike budata welie ya eyi nguzogide, puncture iguzogide, tensile onwunwe na-ebelata ịka nká usoro.

5. High ịdị ọcha nano diamond agaghị eme ka ndu jụrụ, ka ọ nwere ike ọtụtụ-eji na ọgwụ, ndu na ịchọ mma ubi n'ihi na nke nnukwu kpọmkwem elu ebe, ike adsorption ike.

Ajuju gi

Ọ bụrụ na ị nwere ajụjụ ọ bụla. Biko nweere onwe gị ịkpọtụrụ anyị.