Ngwaahịa

Ihe na-emebi emebi na-acha ọcha Alumina Grits

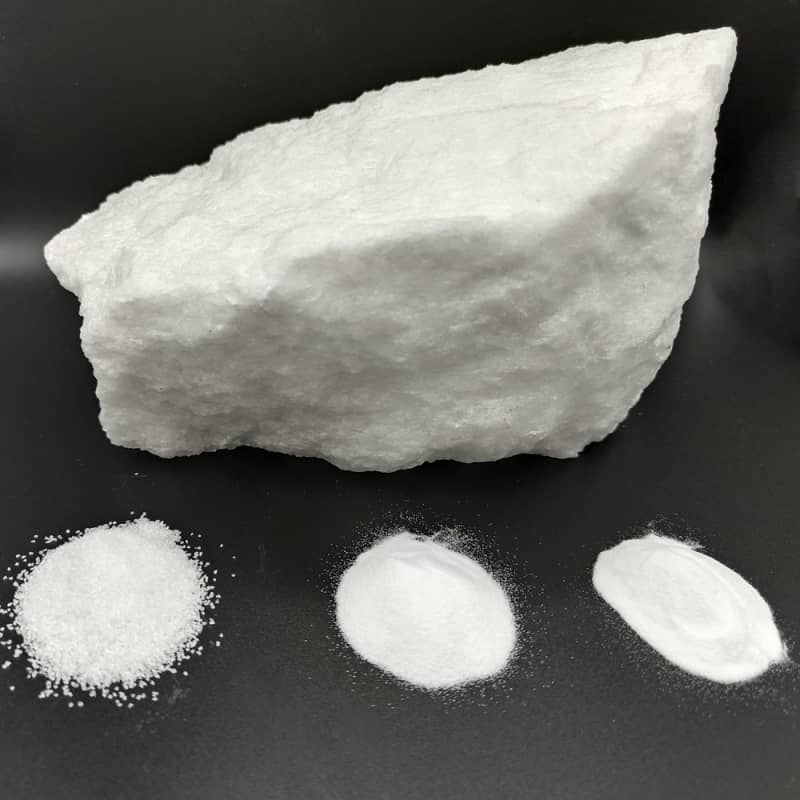

White fused alumina bụ alumina ntụ ntụ dị ka akụrụngwa, mgbe niile n'elu 2000 ℃ elu okpomọkụ na-agbaze ọkụ ọkụ eletrik, mgbe agbajikwa plastic, magnetik nkewa na ígwè, ihuenyo kewara n'ime ụdị dị iche iche nke urughuru size, ok udidi, elu siri ike, granular ụdị nkuku siri ike. dị elu karịa aja aja fused alumina bụ ubé, ubé ala siri ike, ike ọnwụ ike na chemical kwụsie ike dị mma, nwere ezigbo mkpuchi.

A na-eme alumina na-acha ọcha fused alumina nke dị elu dị ọcha dị ala-sodium alumina ntụ ntụ site na-agbaze na oke okpomọkụ, na-eme ka kristal dị jụụ, wee gwepịa ya.Ihe na-acha ọcha fused alumina grit nọ n'okpuru nchịkwa siri ike iji mee ka nkesa nha ọka na ọdịdị na-agbanwe agbanwe.

A na-ejikarị eme ihe n'ime ihe nkedo ladle, ihe ndị na-agba ọsọ ígwè, ihe ngwakọta egbe egbe na ngwaahịa ndị ọzọ monolithic;

N'ihi na ekara refractory ihe, ọ na-bụ-eji na elu-edu akụrụngwa nke corundum brik, corundum mullite, refining ígwè porous plọg brik, integral ịgba egbe, steelmaking na-aga n'ihu nkedo ụlọ ọrụ.

A pụkwara iji ya mee ihe dị ka ihe maka polishing, nkedo ziri ezi, spraying na mkpuchi, ceramik pụrụ iche

Na-acha ọcha, kristal α karịrị 99%, ịdị ọcha dị elu, isi ike dị elu, na ịdị elu siri ike, ike ịkpụ ike, nkwụsi ike kemịkalụ siri ike, yana mkpuchi siri ike.

| Mohs isi ike | 9 |

| Nnukwu njupụta | 1.75-1.95g / cm3 |

| Nnukwu ike ndọda | 3.95g / cm3 |

| Njupụta olu | 3.6 |

| ogo agbaze | 2250 ℃ |

| Refractory ogo | 2000 ℃ |

A na-eji ya eme ihe na-emegharị emegharị, nke a na-atụgharị

| Njirimara | 0-1 1-3 3-5m/m | F100F200F325 | |||

| Uru ekwe nkwa | Uru a na-ahụkarị | Uru ekwe nkwa | Uru a na-ahụkarị | ||

| Ngwakọta kemịkalụ | Al2O3 | ≥99.1 | 99.5 | ≥98.5 | 99 |

| SiO2 | ≤0.4 | 0.06 | ≤0.30 | 0.08 | |

| Fe2O3 | ≤0.2 | 0.04 | ≤0.20 | 0.1 | |

| Na2O | ≤0.4 | 0.3 | ≤0.40 | 0.35 | |

A na-eji maka abrasives, mgbawa, egweri

| Ụdị Njirimara | Ọka | ||

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

| Uru ekwe nkwa | Uru a na-ahụkarị | ||

| Ngwakọta kemịkalụ | Al2O3 | ≥99.1 | 99.5 |

| SiO2 | ≤0.2 | 0.04 | |

| Fe2O3 | ≤0.2 | 0.03 | |

| Na2O | ≤0.30 | 0.2 | |

A na-eji maka abrasives, lapping, Polishing

| Ụdị Njirimara | Micropowder | |||

| "W" | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

| "FEPA" | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | |||

| "JIS" | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 4000# 6000# 10000 | |||

| Uru ekwe nkwa | Uru a na-ahụkarị | |||

| Ngwakọta kemịkalụ | Al2O3 | ≥99.1 | 99.3 | |

| SiO2 | ≤0.4 | 0.08 | ||

| Fe2O3 | ≤0.2 | 0.03 | ||

| Na2O | ≤0.4 | 0.25 | ||

1.There dịghị mmetụta banyere agba nke esichara akụkụ.

2.Ọ nwere ike iji mee ihe na usoro ebe a na-amachibido ihe fọdụrụ na ntụ ntụ ígwè.

3.Shaping grains dị nnọọ mma maka mmiri mmiri na-agba mmiri na ọrụ polishing.

1.Sandblasting, polishing na egweri nke ígwè na iko.

2.Filling nke agba, mkpuchi na-eguzogide ọgwụ, seramiiki, na glaze.

3.Ime nke igwe na-egweri, akwụkwọ aja na akwa emery.

4.Production nke seramiiki filter membranes, tubes seramiiki, efere seramiiki.

5.N'ihi na ojiji nke eyi na-eguzogide ala.

6.Aja nke bọọdụ sekit.

7.Sandblasting nke ụgbọ mmiri, ụgbọ elu engines, ụgbọ oloko track na elu ozu.

8.Various na-acha ọcha fused aluminum oxide grains nwere ike ịmepụta dị ka ndị ahịa si dị iche iche chọrọ.

Ajuju gi

Ọ bụrụ na ị nwere ajụjụ ọ bụla. Biko nweere onwe gị ịkpọtụrụ anyị.